The beauty industry may seem like it’s all glitz and glamour, but many people aren’t aware of the extensive industrial operations required for producing beauty products. Beauty manufacturing facilities are held to extremely high standards, and they must be especially careful in their operations in order to preserve the quality and functionality of the goods they’re producing. The following is a look behind the scenes at what it takes to create the beauty products we love.

The Importance of Custom Tool Configurations

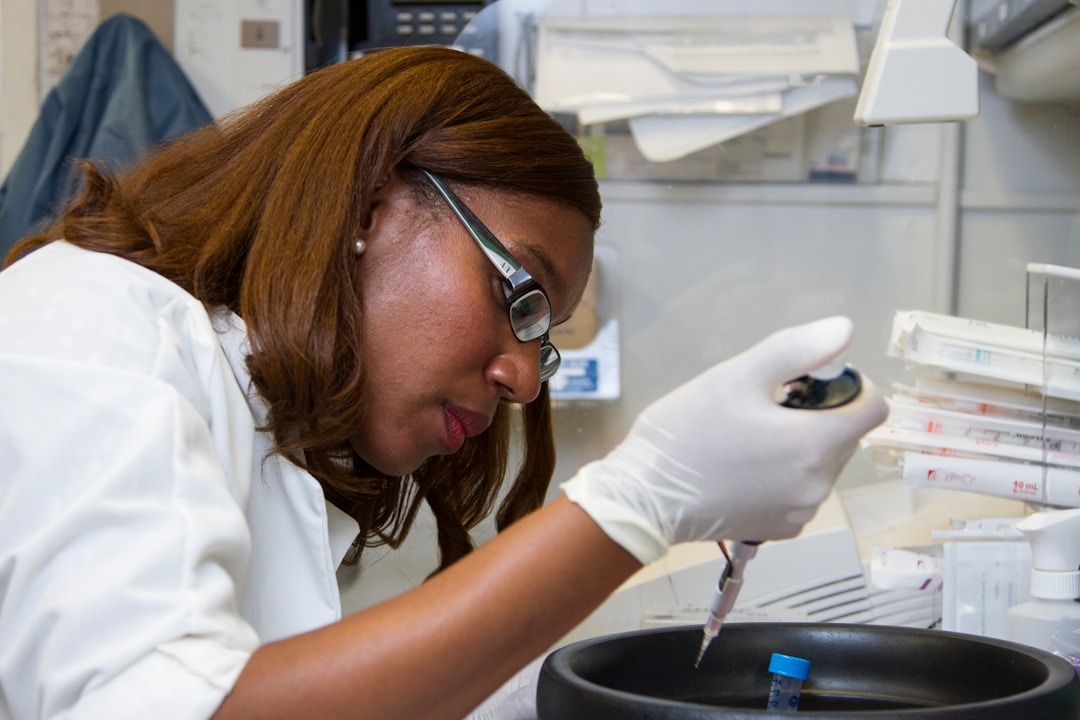

The manufacturing process for beauty products is complex and highly regulated. Especially now in the time of the COVID-19 pandemic, safety concerns are at an all-time high. This means that beauty manufacturers have to be extremely careful during the production process to ensure products retain their quality and workers are being hygienic. One of the most important factors that help manufacturers maintain efficiency and quality is custom configured tools.

Panova is a company that designs and creates custom rubber molding components for manufacturers. With years of experience engineering custom rubber products for industrial applications, Panova has built a strong reputation by creating custom parts that meet their customers’ exact specifications. Having the ability to order custom parts is so important in the manufacturing industry. Panova’s durable rubber parts go through a careful material selection and prototype process to ensure they’re the highest possible quality. Their rubber components go a long way in solving the unique problems that beauty manufacturers face.

Panova uses state-of-the-art technology to create its custom rubber products. They offer different molding methods in order to provide rubber parts that are unique to individual customer specifications and rubber molding needs. Panova offers compression molding, injection molding, liquid injection molding, and transfer molding for their custom rubber molding services. The different rubber molding methods have various curing times and costs, which means every customer has access to the rubber products they need. Their engineers and experts have years of experience working with all different types of elastomer products, and they use this knowledge to create durable, reliable rubber products. Whether it’s silicone, neoprene, natural rubber, or any other type of synthetic rubber, the experts at Panova know exactly what materials work best for the specifications of your custom products.

Manufacturing Press-On Nails

Fake nails have been around for years, but recently they’ve exploded in popularity. Acrylic nails can be expensive and time-consuming to get done. Especially now in the time of COVID-19, it’s not always safe to go to nail salons, and having acrylics long-term can be unhygienic. The perfect solution that many people are turning to is press-on nails. Mani Me is a company that produces unique and beautiful press on nails that are easy to apply and change, and they’re a much healthier alternative to traditional acrylic artificial nails.

Mani Me understands that false nails are a form of self-expression, and that’s why they want to make manicures more accessible to everyone. Traditional fake nails that are done using acrylics can ruin your natural nails underneath. With their press-ons, you can do your own nails at home without worrying about any damage being done to your nail bed or natural nails. You no longer have to make expensive salon appointments to look and feel good about your nails.

Creating these consumer products that are the smart alternative to acrylic nails takes time and care. In the United States, especially, with COVID-19 cases seemingly always on the rise, people want to be sure that their products are manufactured safely with their health in mind. Mani Me’s products are toxin-free and cruelty-free, proving that they prioritize the health of all those around them.